A new type of cover has been produced for the Thor offshore wind farm, named flange covers. These flange covers will be available again in the course of 2025 for use in other offshore wind farms. We have previously achieved success with supplying sustainable monopile covers for the Hollandse Kust Zuid offshore wind farm. These covers have been brought back after use and are currently reused for other projects, highlighting the circularity and sustainability of the product.

In the offshore wind industry, reuse is a key to a sustainable future. That is why we have developed a reusable flange cover that extends the lifespan of crucial components while minimizing waste. 72 flange covers are currently being used at the Thor offshore wind farm and will be available in the course of 2025. This is the opportunity to integrate circular solutions into your offshore operations! More information about how these covers can also make your project more sustainable? Contact us!

Up to now three types of covers have been used on monopiles by the offshore industry. Tent covers, steel- and aluminium covers. All three have disadvantages. Tent covers are not suitable in wintertime. At high wind speeds there is a risk that they are blown away, contaminate the sea and leave the monopile unprotected. The steel and aluminium covers are quite expensive and the recycling process of the cover requires a lot of energy again with aluminium being the top energy consumer. As monopiles often differ in diameter per project, none of the steel or aluminium MP covers have been reused on a new project up to today.

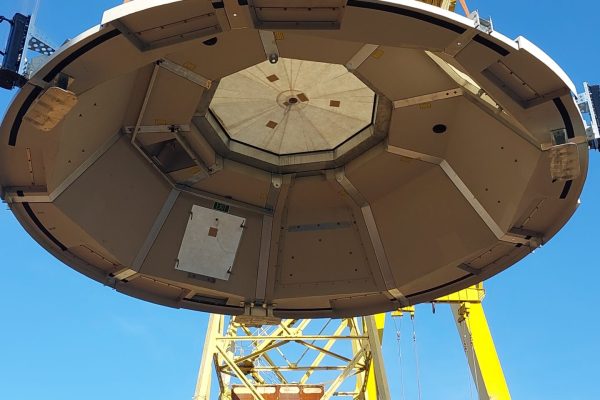

The Composite Monopile Cover is an ingenious and sustainable design, composed with unconventional materials. The construction consists of different fiber reinforced polyester panels and looks a little bit like pieces in a pie. The idea behind the different panels is that you can reuse the top panels of the cover for every diameter of offshore monopile which is currently on the market. Without a cover, the work platform inside the monopile can become wet and slippery from rain or splash water and soiled by bird faeces. Our covers ensure a safe and healthy working environment for all offshore workers.